Spool holder for 3 kg spools

The spool holder on my MK4S printer is only suitable for spools of 1 kg filament. While these are fine for small prints, for larger prints it is preferable to use larger spools.

Initially I used two support cradles where each to the rims of the spool runs on two roller bearings. This had some problems in that it tended to bind and then the spool could be pulled off the bearings. After this caused the failure of an overnight print job I wanted a proper spool holder.

Not being satisfied by designs I could find online I designed my own, for spools up to 3 kg.

Requirements

When desiging this spool holder, I had the following prerequisites in mind.

- Simple.

- Stable.

- Suitable for spools up to 3 kg filament;

- 53 mm center hole

- 100 mm wide

- The individual parts should fit on my Prusa MK4S.

- The axis of rotation should be in the center of the spool for smooth unrolling.

- Use off-the-shelf fasteners if needed.

Design

Since 3D printed parts are mostly hollow, we don’t need to explicitly design thin walled structures such as for injection molding.

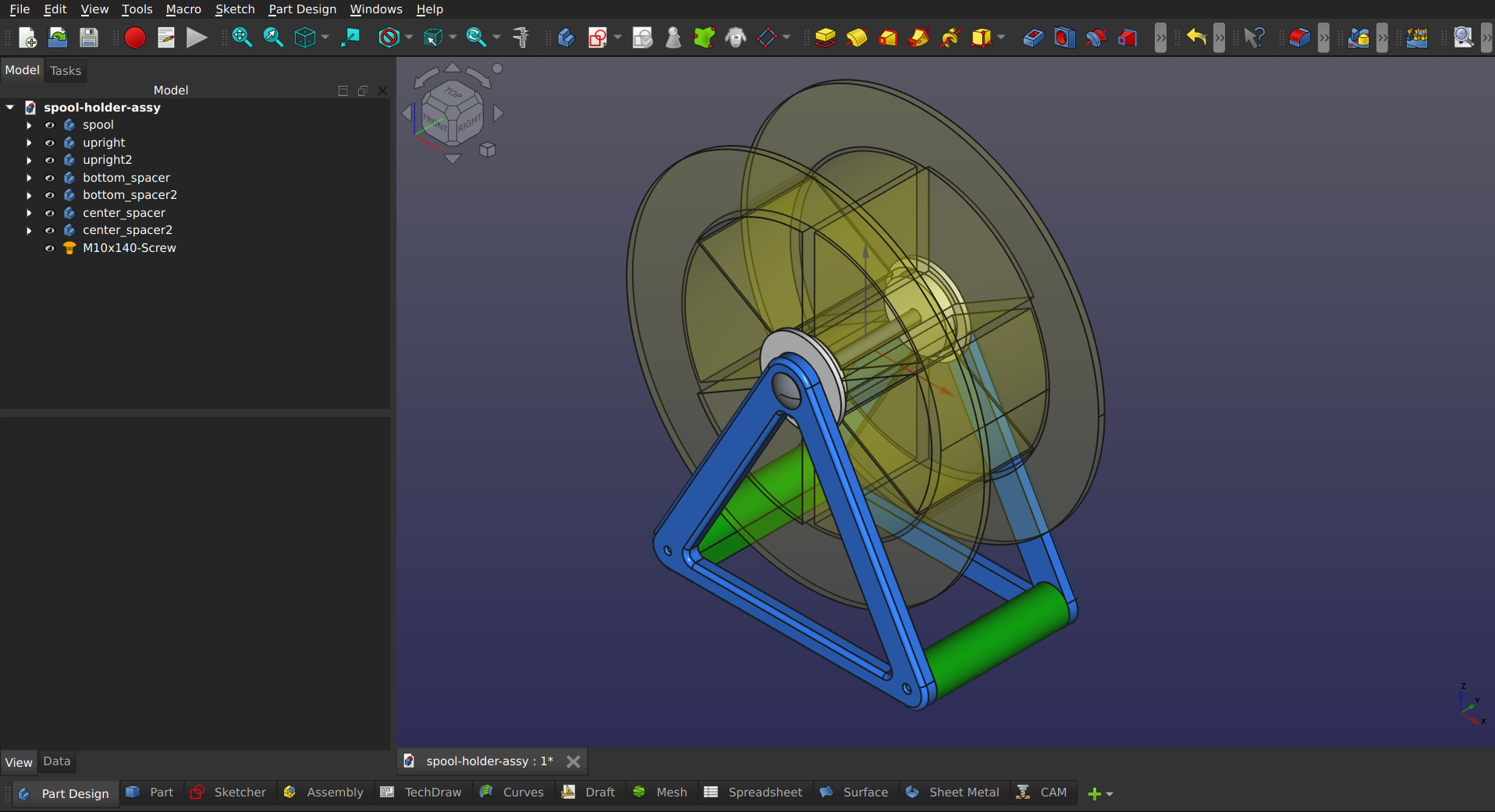

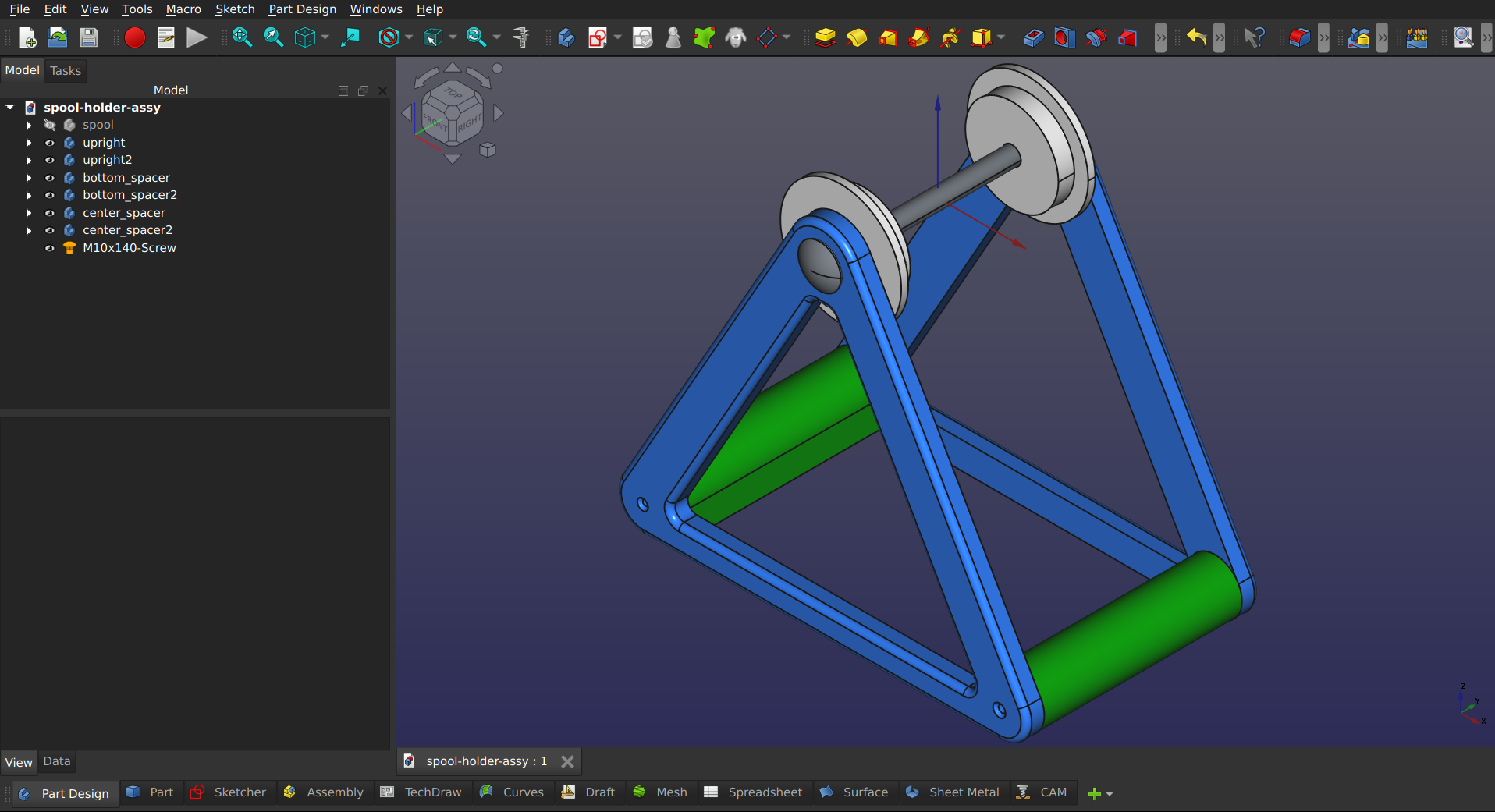

The basis of the design are two (blue) triangular uprights, separated by two (green) spacers on the bottom corners of the triangles. Two (white) center spacers ensure that the axis of rotation is in the center of the spool.

The complete design is available as a freecad file.

This spool holder consists out of three different 3D printed parts, STEP files for each of the parts are linked below.

- upright [blue] (2×)

- bottom spacer [green] (2×)

- center spacer [white] (2×)

Except from the 3D prints the following hardware is needed;

- Countersunk wood screws 3×25 mm (4×).

- DIN 603 carriage bolt M10×140 or M10×160 (1×) and M10 nut.

The wood screws are used to screw the uprights and bottom spacers together. An off-the-shelf carriage bolt is used as the axle bacause the design of the head prevents it from rotating and potentially unscrewing.

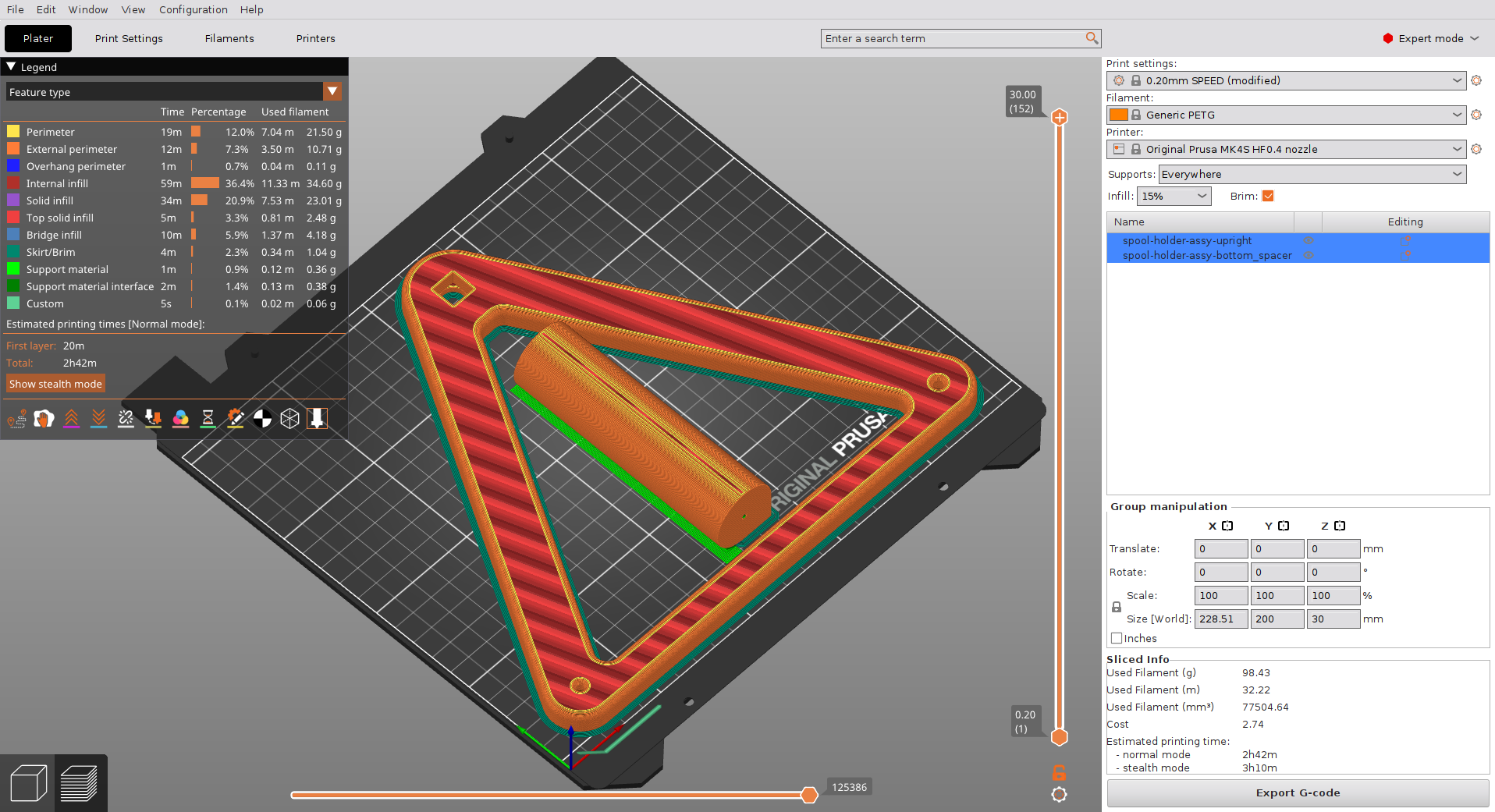

Printing

One upright and one bottom spacer are in a combined print job. Printed in PETG, this job used approximately 100 g of filament. This has to be printed twice to get a functional spool holder.

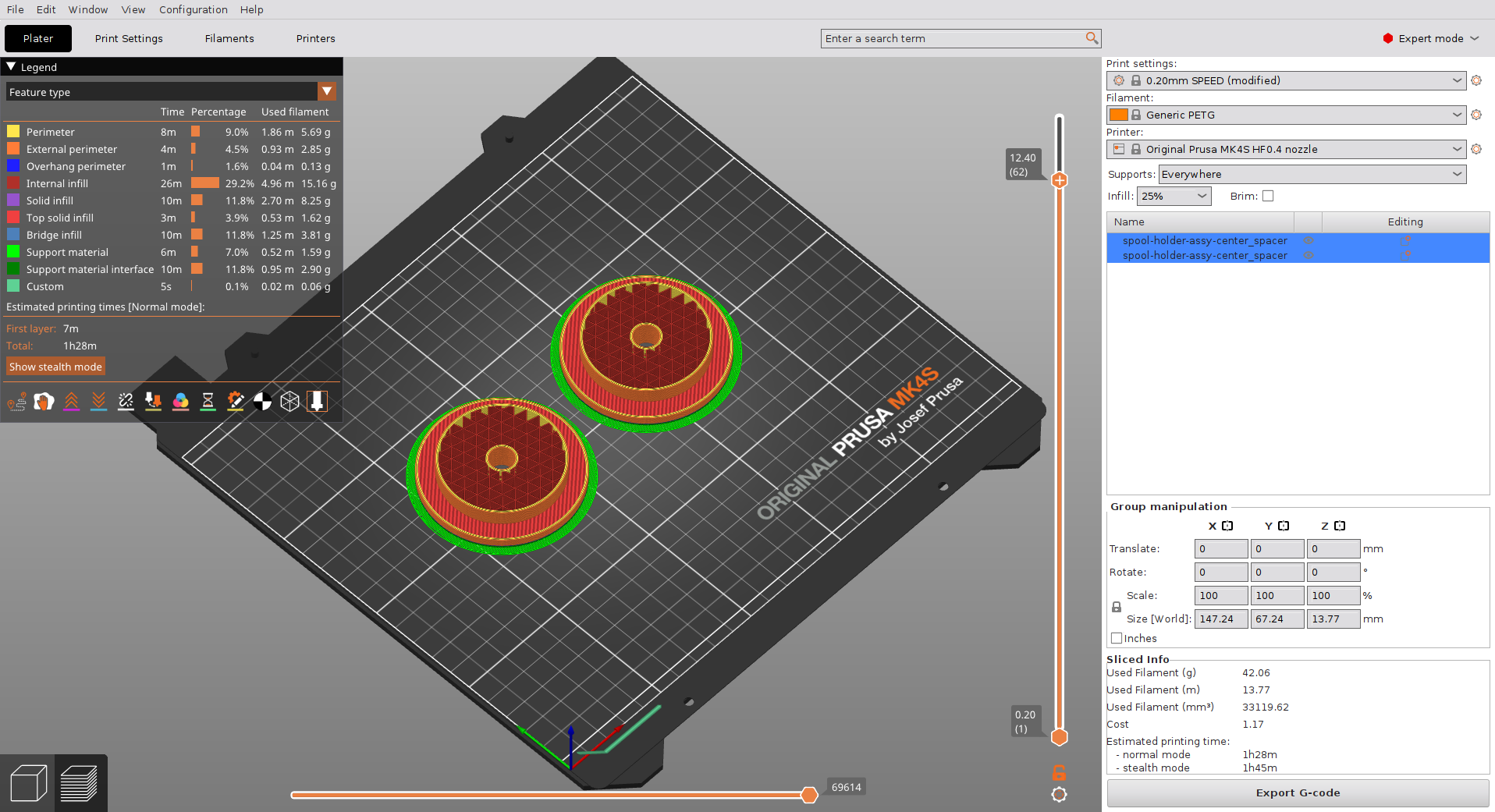

The two center spacers are in a separate print job. In PETG they require 43 g of filament.

The spool holder can be used without them but it is not recommended. Without the center spacers unrolling requires more force.

Assembly

Remove the parts from the print bed and cut off the brim. Peel off the support from the bed-side of the center spacers.

Use four countersunk wood screws 3×25 mm to screw the two bottom spacers between the uprights. The uprights should be placed such that the screw heads fit into the chamfered holes in the uprights. The square sides of the holes at the top of the uprights should be facing outward.

Place the center spacers in the spool and place it between the uprights. Align the holes in the center spacers with the holes in the uprights and push the carriage bolt through. Secure the carriage bolt with the nut.

For comments, please send me an e-mail.