Drill bushings in 3D printed parts

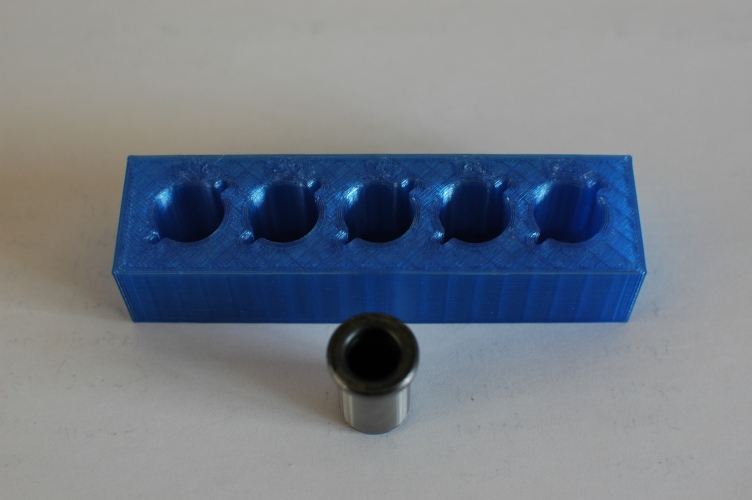

In order to make a 3D printed drilling jig last longer, I wanted to put drill bushings in it. Being new to 3D printing, I decided to print a test piece to see what the size of the holes should be for a snug fit.

The drill bushing I used for testing is for a 10 mm drill bit. It has a 15 mm outside diameter measured with a Vernier caliper. Using a micrometer, the outside measures ⌀15.02 mm.

The technical drawing of the test piece is shown below. It was modelled in FreeCAD.

It has holes from 14.8 mm to 15.2 mm incrementing in steps of 0.1 mm. The holes are designed with relief slots so that the holes can easier accept a press fit.

After exporting the model as a STEP-file, it was imported into PrusaSlicer.

Note

STL files are only an approximation of the original geometry! How good that approximation is depends on the settings used when exporting the STL. One of the reasons STL files are popular is that they are easy to read because it is basically just a set of triangles. So for optimal accuracy it is best to use a proper geometry exchange format like STEP.

The following slicer parameters are used:

- material: PETG,

- nozzle: 0.4 mm,

- layer height 0.2 mm,

- three perimeter layers,

- 20% infill,

- extruder temperature 235°C,

- bed temperature 85°C.

All the other parameters were according to the defaults for this printer in PrusaSlicer. The part was printed in PETG on my Prusa MK4S.

After the print had cooled down, I tested the fit of the bushing in the holes.

| Nominal size | Result |

| ⌀15.2 mm | sliding fit |

| ⌀15.1 mm | light interference fit |

| ⌀15.0 mm * | interference fit |

| ⌀14.9 mm * | interference fit |

| ⌀14.8 mm | does not start |

The holes marked with “*” are the sizes I would recommend.

A pair of water pump pliers was required to push the drill bushing in to the ⌀15.0 mm and ⌀14.9 mm holes. Using the pliers to grip the flange of the bushing, the bushing could be extracted from those holes; the ⌀14.9 mm required significantly more effort.

In conclusion, a hole with a nominal dimension equal to the outside dimension of the drill bushing (or slightly smaller) works well for PETG under the aforementioned parameters.

For comments, please send me an e-mail.