FEA with Calculix (3)

This is the third installment of a series of articles about how to analyze sandwich structures with FEA.

It might be a good idea to read part 1 and part 2 first.

In this part we will look at a simplified simulation of a three-point bending test of a sandwich panel.

The general layout of a three point bending test is shown below.

A relatively slender beam is laid up on two supports. Then a displacement is applied in the middle of the beam, and the force that occurs there is measured with a load-cell.

Looking at the problem geometry, we would expect the highest stresses to occur in the top skin at point C. This is the point where all the external downward force is applied on the product. The balancing upward force is divided over two supports, so stresses there will be lower.

Using the pre-processor to generate the mesh

Since this situation is symmetrical, we will only simulate half of it (C−B). When showing the results they will be mirrored to show the whole beam. And instead of moving point C downwards, we will move point B upwards. That amounts to the same deformation in the sandwich, just with another reference point.

For simplicity, we will apply constraints and displacements directly to the nodes. In reality, the beam usually rests on cylindrical supports, but that is for a later article.

We will use the domain-specific language (“DSL”) of the CalculiX

pre-processor cgx to generate the geometry.

We start with defining the parameters for the model.

# Dimensions:

# length in m of half the sample

valu L / 0.56 2

# detailed length

valu D / L 10

valu D2 * D 2

valu Lp3 - L D2

# width in m

valu B 0.1

valu B2 / B 2

# total thickness in m

valu T 0.031

# top skin thickness in m.

valu t1 0.0015

# bottom skin thickness in m.

valu t2 0.0015

# core thickness in m

valu tk - T t1

valu tk - tk t2

# Divisions that determine element count.

# Note that for second order elements, two divisions is one elemen!

# divisions in length.

valu ldiv 40

# divisions in length.

valu ddiv 10

# devisions in width.

valu bdiv 12

# divisions in skin height.

valu tbdiv 6

# divisions in core height

valu tkdiv 6

Next we create the volumes.

# Bottom skin

seto skin2

pnt ! 0 0 0

swep skin2 p2 tra D 0 0 ddiv

swep p2 p3 tra Lp3 0 0 ldiv

swep p3 new tra D 0 0 ddiv

swep skin2 new tra 0 B 0 bdiv

swep skin2 if1 tra 0 0 t2 tbdiv

setc

# Core

seto core

copy if1 if2 tra 0 0 0

swep if2 if3 tra 0 0 tk tkdiv

setc

# Top skin

seto skin1

copy if3 if4 tra 0 0 0

swep if4 top tra 0 0 t1 tbdiv

setc

Note that in the length the model is divided into three parts. The reason for that is that we want the mesh to be finer near the points where the load and displacement constraints are applied because that is where the stress concentrations will be.

Generally, one would want the mesh near a stress concentration fine enough that the effects of the stress concentration are spread of several elements. Otherwise the way the element is defined (the shape functions) will determine how the stress concentration looks.

Next, we can create the mesh, create the node sets for the constraints. In this case for this simple sandwich we will use equations to tie the different materials together.

See part 1 on why we want to do this instead of just make the elements from different materials share nodes.

# Constraints

seta nodes n all

enq nodes fix rec 0 _ T 0.0001 a

enq nodes symm rec 0 _ _ 0.001 a

setr symm n fix

enq nodes disp rec L _ 0 0.0001 a

# Write contact equations

send if1 if2 abq areampc 123

send if3 if4 abq areampc 123

# Remove nodes on dependant contact surfaces from constraints

setr fix n if1 if3

setr symm n if1 if3

The CalculiX manual recommends using tie constraints, but equations also work. The potential problem with using equations is that a node can only appear on the dependant side of an equation once, otherwise the solver run will fail. This can be hard to do with the pre-processor on complex parts, and tie constraints do not have that problem.

The last pre-processing step involves writing the data.

# Write data

send all abq

send skin2 abq nam

send core abq nam

send skin1 abq nam

send fix abq nam

send symm abq nam

send disp abq nam

quit

Using the quit command enables us to use the -bg option of cgx.

This suppresses the graphics output for the creation of the mesh.

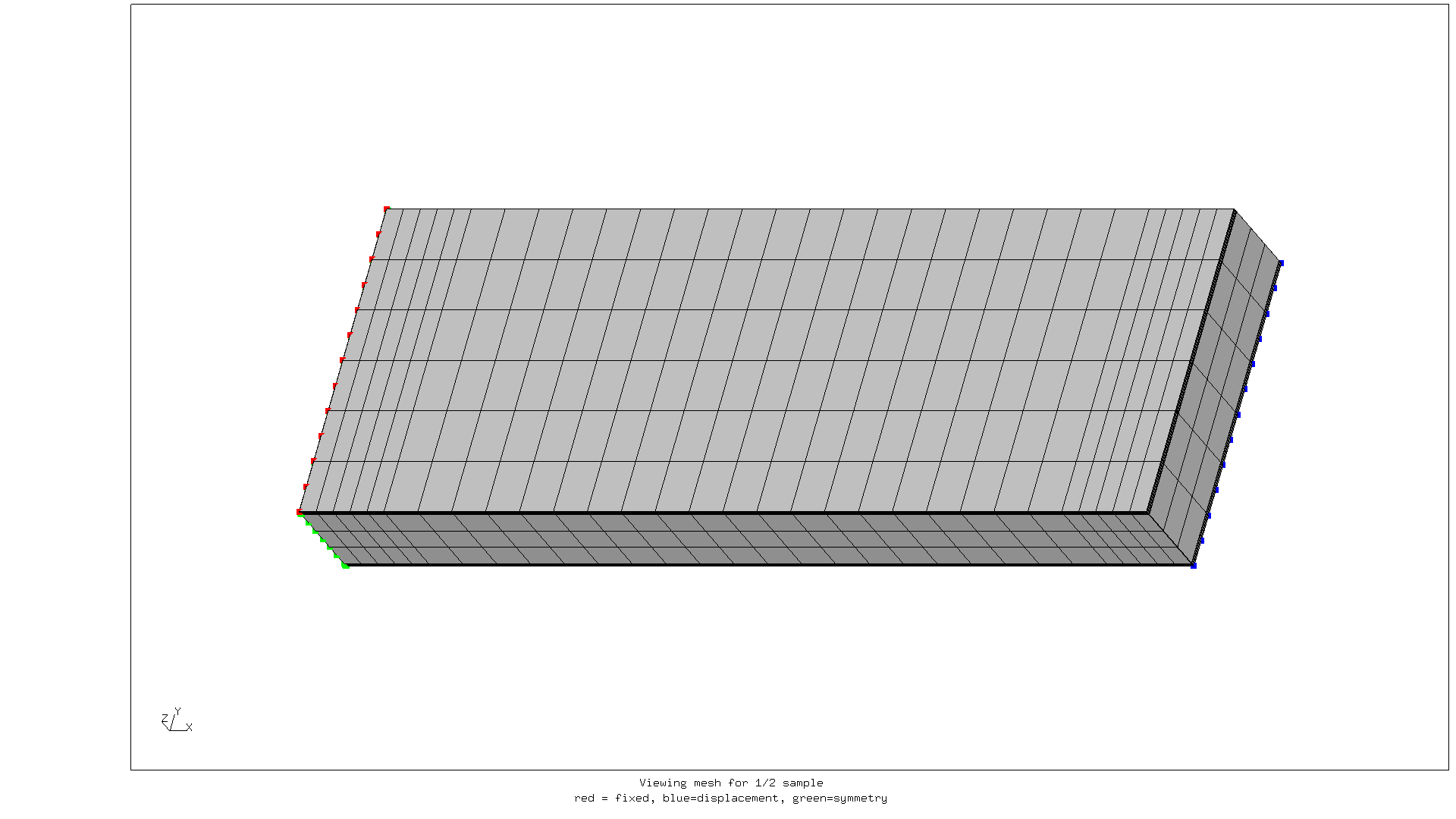

The finished mesh is shown below.

One can see how the mesh size is smaller near the ends. The red nodes will be fixed in all directions. The green nodes will be fixed in x-direction. The blue nodes will be subject to a forced displacement.

Writing the solver command file

First we need to import all the files generated by the preprocessor.

*HEADING

Three-point bending of sandwich

** Import geometry

*INCLUDE, INPUT=all.msh

*INCLUDE, INPUT=core.nam

*INCLUDE, INPUT=disp.nam

*INCLUDE, INPUT=fix.nam

*INCLUDE, INPUT=if1.equ

*INCLUDE, INPUT=if3.equ

*INCLUDE, INPUT=skin1.nam

*INCLUDE, INPUT=skin2.nam

*INCLUDE, INPUT=symm.nam

Then we apply the boundary conditions.

** Fix the middle of the beam.

*BOUNDARY

Nfix,1,3

Nsymm,1,1

Next come the material definitions. This sandwich consists of a Rohacell 71IG core, with a stainless steel (1.4301) skin on top and an aluminium (EN AW-5083) skin on the bottom.

In tests like these, materials are generally tested until failure or permanent deformation occurs. So we have to take plastic deformation into account. Metals are well-known to exhibit plastic behavior. We have used the Ramberg-Osgood equation to generate the plastic deformation curve for the metal skins.

The metal materials are defined as follows.

** Steel

*MATERIAL, NAME=M1.4301

*ELASTIC, TYPE=ISO

200e9,0.30,293

*PLASTIC, HARDENING=COMBINED

205e6,0.003025,293

300e6,0.019373,293

400e6,0.095501,293

475e6,0.253618,293

515e6,0.402575,293

*DENSITY

7900

** Aluminium

*MATERIAL, NAME=M_EN_AW_5083

*ELASTIC, TYPE=ISO

71e9,0.33,293

** H111: Rp = 150, Rm = 310, em = 0.13

*PLASTIC, HARDENING=COMBINED

150e6,0.002,293

175e6,0.00485,293

200e6,0.01046,293

250e6,0.03773,293

280e6,0.0724,293

*DENSITY

2660

For the core foam I decided to use the datasheet properties for compression, since in this case the foam will definitely experience it next to shear. The plastic properties are estimated from a compression test, where the force showed practically no increase after cells started failing.

*MATERIAL, NAME=MrohacellIG71

*ELASTIC,TYPE=ENGINEERING CONSTANTS

73e6,73e6,73e6,0.1,0.1,0.1,29e6,29e6

29e6,293

*PLASTIC

** This is a guess.

1.5e6,0.0,293

1.5e6,0.1,293

*DENSITY

75

As usual, we have to assign materials to the different element sets.

*SOLID SECTION, ELSET=Eskin2, MATERIAL=M_EN_AW_5083

*SOLID SECTION, ELSET=Ecore, MATERIAL=MrohacellIG71

*SOLID SECTION, ELSET=Eskin1, MATERIAL=M1.4301

Here is the *STEP section. It is somewhat different from the earlier examples.

*STEP, NLGEOM

*STATIC

*BOUNDARY

** Forced displacement 10 mm

Ndisp,3,3,10e-3

*NODE FILE

U

*NODE PRINT,NSET=Ndisp

RF

*EL FILE

ZZS,PEEQ

*END STEP

We use the NLGEOM option to tell the solver that nonlinear geometric

effects are to be taken into account.

As a consequence, this will become an iterative calculation.

Inside the step, the *BOUNDARY command is used to enact the forced displacement.

The *NODE PRINT command is used to save the reaction force on the nodes in

the set Ndisp in a .dat file for later use.

Finally, for the elements we not only save the Zienkiewicz-Zhu improved stress (ZZS), but also equivalent plastic strain (PEEQ).

Results

The solver run took around 27 seconds on my i7-7700 class machine. Maximum resident set size was about 0.5 GiB. The solver divided the total displacement into four steps, which each took four to five iterations for the calculations to converge.

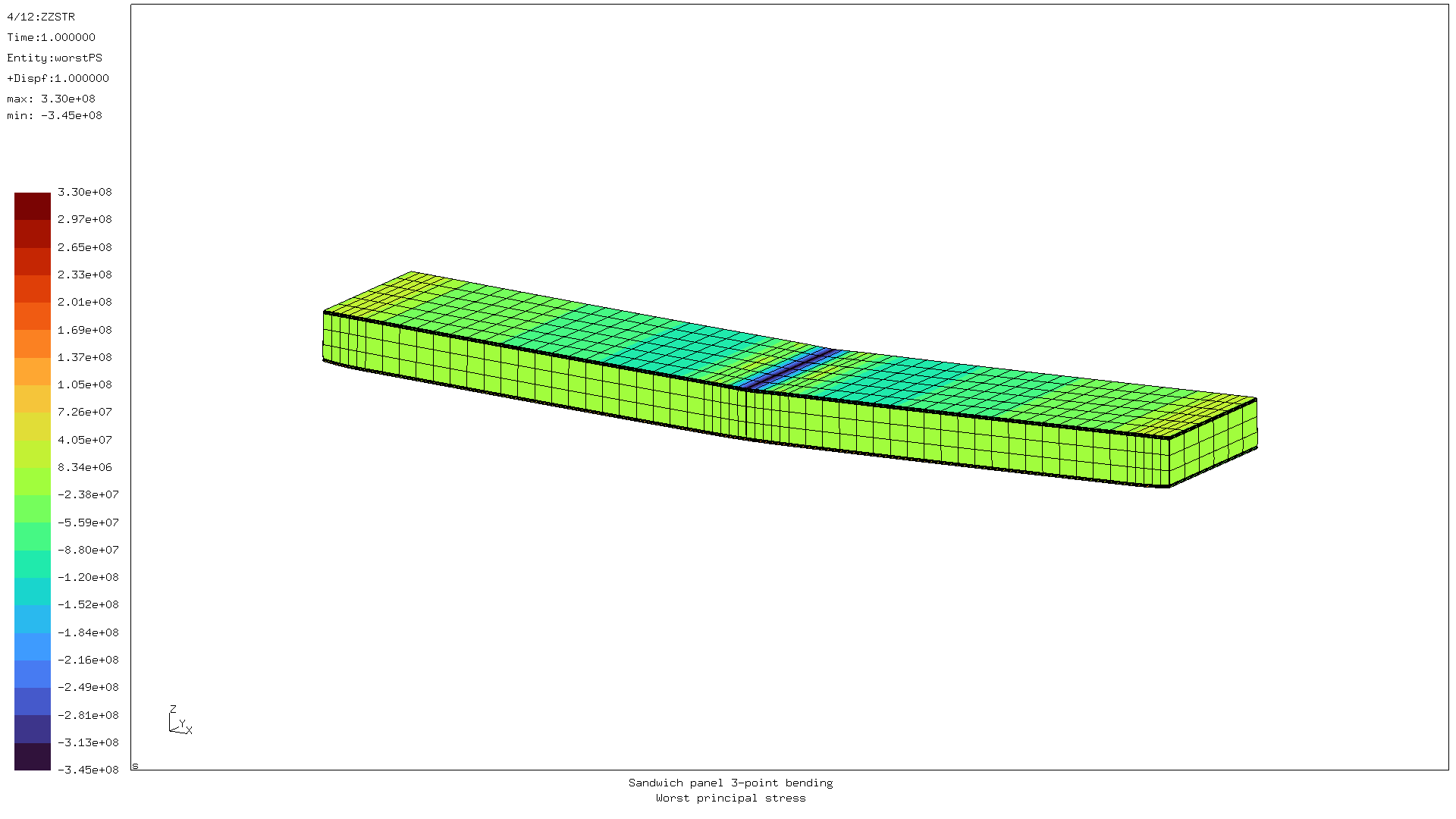

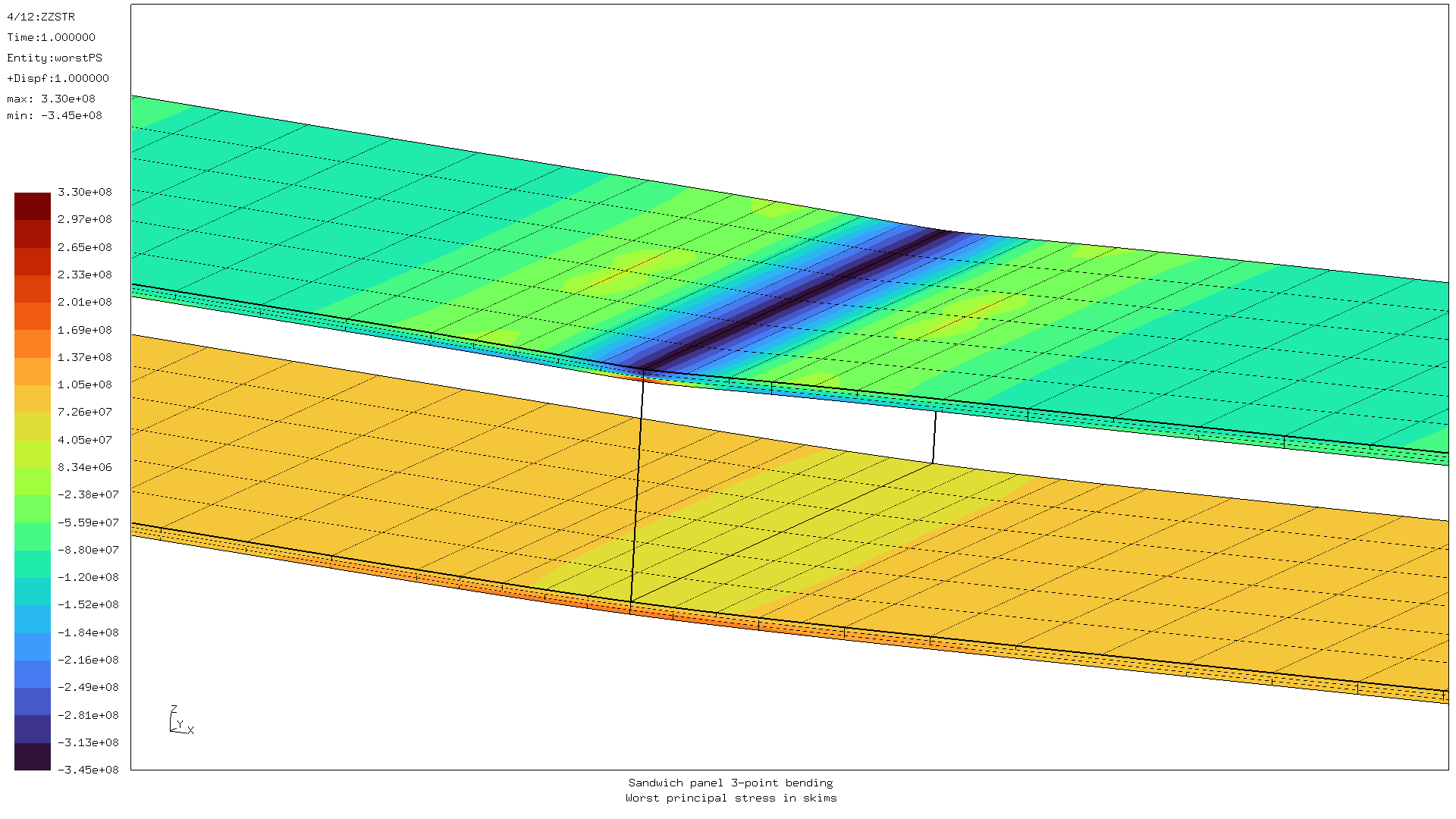

It is clear that the largest compression occurs in the middle of the top skin, as expected. So let’s look at the stress in the skins in more detail.

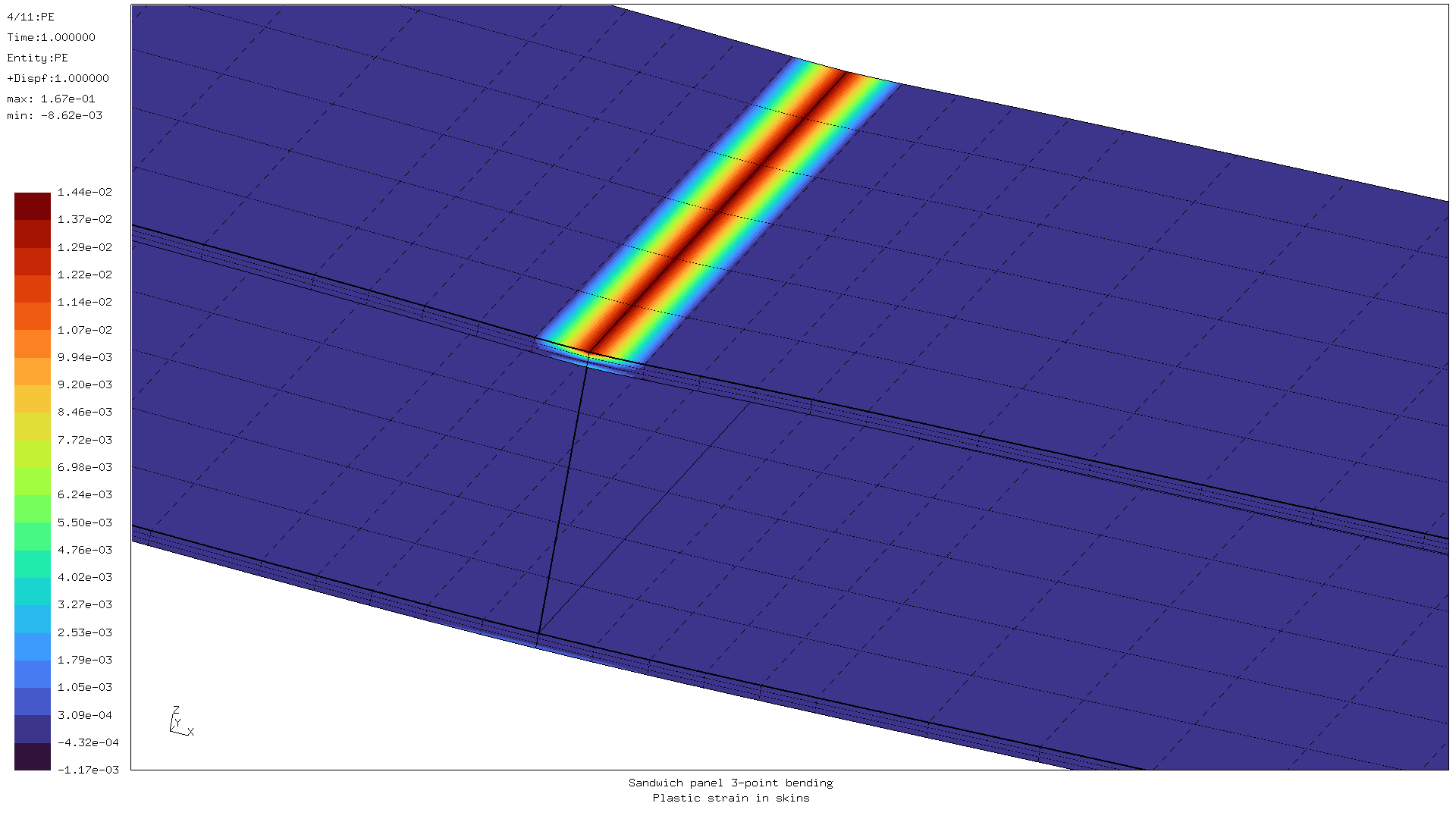

If we look at the side of the top skin we can see that the maximum tension stress also occurs in the top skin, but on its bottom side. This is confirmed if we look at the plastic strain.

The top skin in the middle of the beam is the place where the highest plastic strain occurs in the skin.

The reaction force data for each step is saved in text format in a .dat

file (first two steps shown):

forces (fx,fy,fz) for set NDISP and time 0.2500000E+00

2599 -3.360807E-06 -4.033513E-07 2.057916E+01

2600 -9.987526E-06 8.358038E-07 3.045198E+01

2607 3.979269E-05 -1.930124E-07 5.925281E+01

2729 -8.014658E-06 -9.461500E-08 2.950608E+01

2733 3.352114E-05 2.411522E-07 6.555898E+01

2804 -7.927693E-06 -2.026624E-10 2.993997E+01

2808 3.389915E-05 7.729466E-08 6.561188E+01

2879 -8.013995E-06 9.449739E-08 2.950608E+01

2883 3.389901E-05 -7.687667E-08 6.561188E+01

2954 -9.987691E-06 -8.355860E-07 3.045198E+01

2958 3.352070E-05 -2.414209E-07 6.555898E+01

3029 -3.360673E-06 4.033751E-07 2.057916E+01

3033 3.979238E-05 1.928583E-07 5.925281E+01

forces (fx,fy,fz) for set NDISP and time 0.5000000E+00

2599 4.537729E-08 -4.412250E-09 4.159682E+01

2600 1.061603E-07 -1.883946E-09 6.000885E+01

2607 -2.892327E-07 2.667418E-09 1.151232E+02

2729 8.682119E-08 -3.611315E-10 5.755900E+01

2733 -2.277925E-07 4.297348E-10 1.300878E+02

2804 8.640352E-08 6.263113E-11 5.837196E+01

2808 -2.253813E-07 1.549903E-10 1.302890E+02

2879 8.613001E-08 2.752583E-10 5.755900E+01

2883 -2.249354E-07 -4.085367E-10 1.302890E+02

2954 1.058637E-07 1.811355E-09 6.000885E+01

2958 -2.271329E-07 -3.161963E-10 1.300878E+02

3029 4.525147E-08 4.314001E-09 4.159682E+01

3033 -2.885772E-07 -2.396299E-09 1.151232E+02

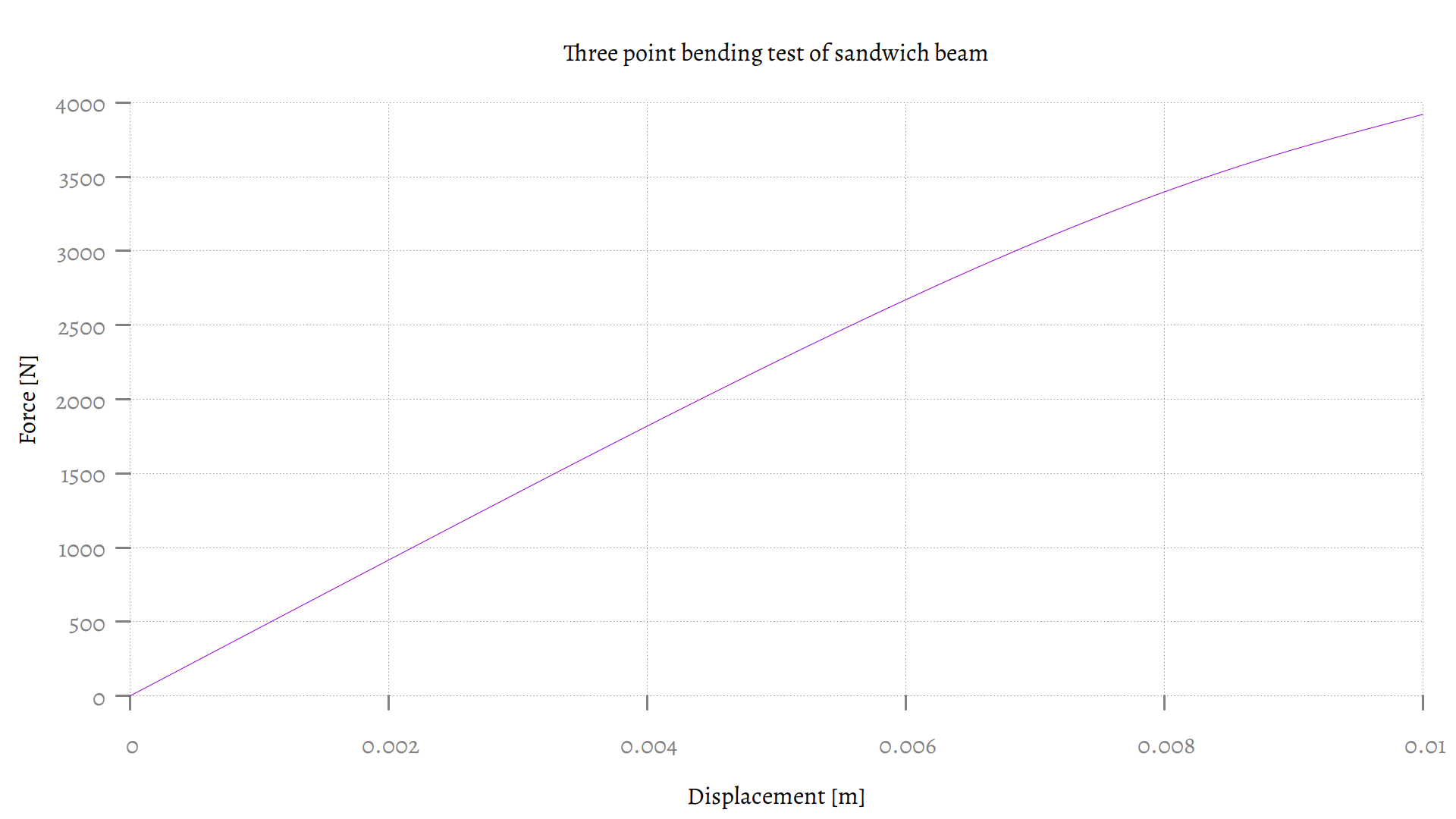

To make a force/displacement graph for this simulation, a small Python script was used to sum the z-forces per step.

disp = 0

zf = 0

print("0.0000 0")

with open("static.dat") as f:

for ln in f:

ln = ln.strip()

if ln.startswith("forces"):

if zf:

print(f"{disp:.4f} {zf:.0f}")

zf = 0

disp = float(ln.split()[-1])*0.01 # m

pass

elif len(ln) > 0:

zf += 2*float(ln.split()[-1])

print(f"{disp:.4f} {zf:.0f}")

The resulting data was turned into a plot with gnuplot.

This graph was a good match when actual samples were subjected to the three point bending test.

For comments, please send me an e-mail.

Related articles

- Corrugation against buckling

- FEA with Calculix (2)

- FEA with Calculix (1)

- Element names in Calculix

- FEA based on STEP geometry using gmsh and CalculiX